Understanding the Difference Between Semi-Rigid Ducting, Flexi Duct, and Rodent-Proof Ducting

When it comes to air conditioning, heating, and ventilation systems, choosing the right ducting is key to performance, efficiency, and durability. While there are several types of ducting on the market, three of the most commonly discussed are semi-rigid ducting, flexible ducting (flexi duct), and rodent-proof ducting. Each has unique features and ideal applications. Let’s take a closer look at how they differ and where they’re best used.

1. Semi-Rigid Ducting

What it is:

Semi-rigid ducting is made from aluminum or galvanized steel that can be bent into position while retaining its shape. It has a smooth internal surface which promotes efficient airflow.

Key benefits:

- High durability and resistance to crushing or tearing.

- Smooth inner walls reduce air resistance and improve energy efficiency.

- Easier to clean and maintain than flexible ducting.

- Fire-resistant and suitable for high-heat applications.

Applications:

Semi-rigid ducting is ideal for:

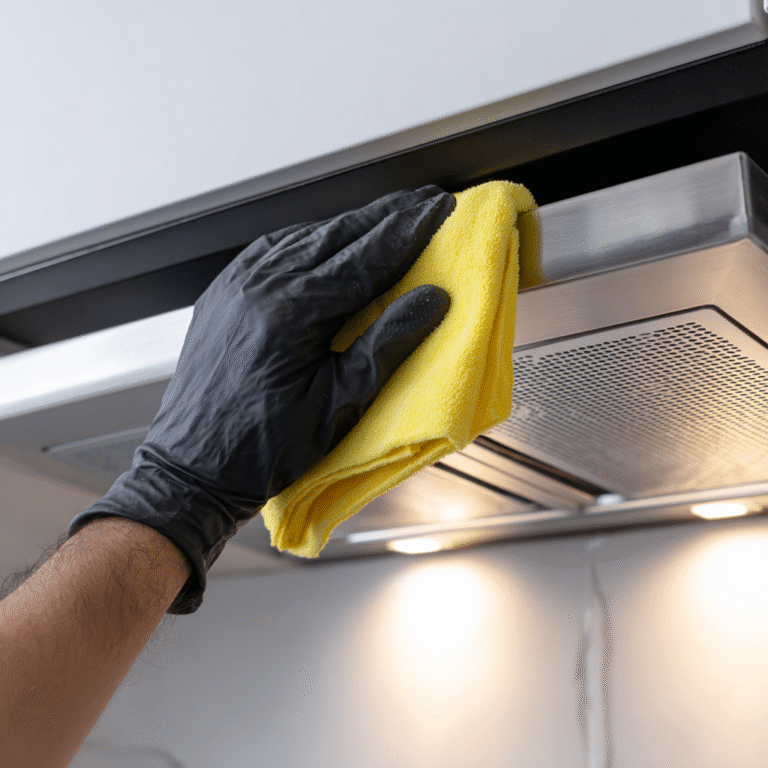

- Kitchen rangehoods

- Clothes dryers

- Exhaust fans

- Commercial ventilation systems

It’s often used where space allows for a more fixed duct and where performance and longevity are priorities.

2. Flexible Ducting (Flexi Duct)

What it is:

Flexi ducting consists of a wire coil covered with a plastic or aluminum outer layer and insulation. It’s lightweight and highly bendable, making it easy to install in tight spaces or around obstacles.

Key benefits:

- Very flexible and easy to install.

- Cost-effective and lightweight.

- Good for applications where rigid ducting won’t fit.

Applications:

Commonly used in:

- Residential heating and cooling systems (HVAC)

- Air distribution in ceilings or under floors

- Temporary or low-pressure ventilation setups

However, because of its corrugated inner surface, flexi duct can reduce airflow efficiency if installed improperly or over long distances. It’s important to avoid sharp bends and compressions during installation.

3. Rodent-Proof Ducting

What it is:

Rodent-proof ducting is reinforced with a stainless steel or wire mesh layer to prevent rats and mice from chewing through the duct. It’s designed to offer the same airflow performance while protecting the system from pest damage.

Key benefits:

- Prevents rodent infestations and duct damage.

- Extends system life and reduces maintenance costs.

- Ideal for areas where rodent activity is common.

Applications:

Perfect for:

- Rural or bushland properties

- Roof cavities and subfloors prone to rodent access

- Commercial and industrial sites needing durable pest-resistant systems

Rodent-proof ducting can be either semi-rigid or flexible, depending on the product type and installation needs.

Choosing the Right Ducting

When selecting ducting for your project, consider:

- Environment: Is the area prone to pests or moisture?

- Space constraints: Do you need flexibility or rigidity?

- Airflow efficiency: Will smooth internal walls make a difference?

- Longevity and maintenance: How long should the system last?

It’s also essential to follow the manufacturer’s specifications when choosing and installing ducting. Each appliance or ventilation system is designed to perform best with specific duct types, diameters, and materials. Using the recommended ducting ensures compliance, safety, and maximum efficiency — and helps avoid warranty or performance issues down the track.